Barriers

Moving machine parts can potentially cause severe workplace injuries, such as crushed fingers or hands, amputations, burns, or blindness. In addition, amputations, lacerations, and abrasions are costly and potentially increase workers' compensation premiums. (Amputation is one of the most severe and crippling types of injuries in the occupational workplace, often resulting in permanent disability.) Due to this fact, OSHA (Occupational Safety & Health Administration) has established a set of standards around machine guarding. The purpose of machine guarding is to protect the machine operator and other employees in the work area from hazards created during the machine's regular operation. That would include risks of concern such as ingoing nip points, rotating parts, reciprocating, transversing, and flying chips & sparks. Any machine part, function, or process that might cause injury must be safeguarded. When the operation of a machine or accidental contact with it could injure the operator or others in the vicinity, the hazards must be controlled or eliminated.

| Wire Machine Guard, Security Cage, Door, and Dock Gates | ||

WireCrafters Physical Wire Machine Guard Learn more about this product |

WireCrafters Style 840 Security Cage  |

WireCrafters Dock Door Cage Pre-Configured Systems  |

Folding Door Security Gate  |

Single Folding Security Gate  |

Double Folding Security Gates  |

Vestil Dock Safety Barricade Gate  |

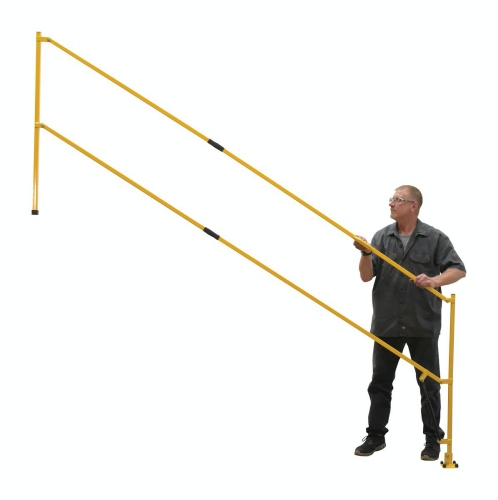

Vestil Economical Safety Swing Gates  |

Vestil Safety Lift Gate  |

Vestil Swivel Dock Gates  |

Vestil Dock Chain Bollard Barrier  |

Vestil Expand-A-Gates Steel-Aluminum-Plastic  |

We have shipping points all over the United States and Canada!